Metallic Epoxy Floor: A Guide to Epoxy Flake Flooring

APC Mica Flake 100g

APC Mica Flake 30g

APC Diamond Holographic Resi Glitter 100g

APC 4.5kg Ultra Flake Highlights

APC 450g Ultra Flake Highlights

APC Hyper Flake 4.5kg

APC Quartz Shield 22.5kg

APC Ultra Flake 4.5kg

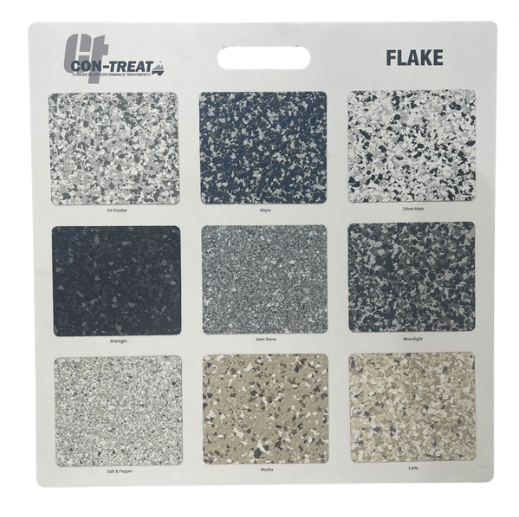

Con-Treat Flake Board

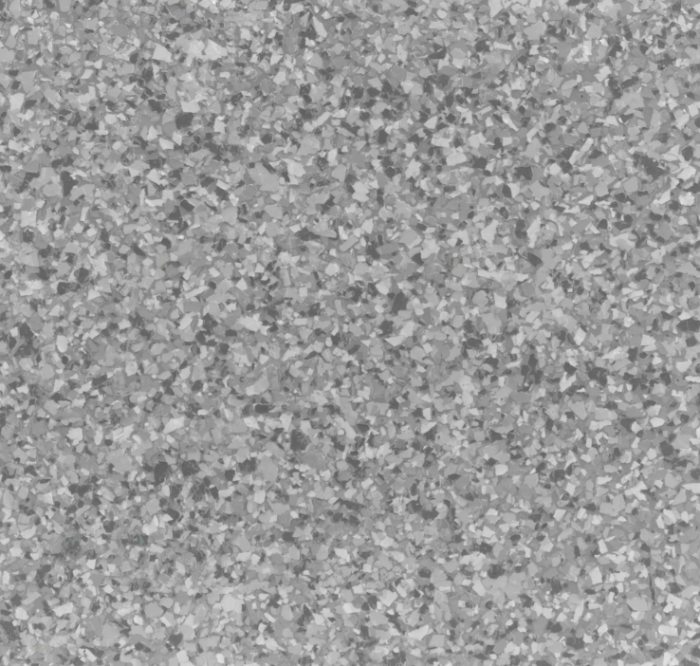

Quartz

Metallic

The key benefits of using flake, metallic, and quartz coatings on concrete surfaces are:

1. Enhanced aesthetics and decorative appeal:

-

Flakes, metallics, and quartz add visual interest, depth, and texture to concrete floors, walls, and countertops.

-

They come in a wide range of colors, sizes, and styles, allowing for customised and unique designs.

-

Metallic coatings provide a luxurious, shimmery finish resembling polished stone or metal.

-

Quartz coatings create a granite-like appearance with a natural, multi-toned look.

2. Increased durability and wear resistance:

- These coatings are typically epoxy or polyurethane-based, providing a hard, durable surface resistant to abrasion, impact, and heavy foot traffic.

- Epoxy flooring is particularly suitable for high traffic areas due to its resistance to wear and tear.

- Quartz in particular adds excellent wear and scratch resistance due to its hardness.

3. Low maintenance and easy cleaning:

- The seamless, non-porous surface created by these coatings makes them stain-resistant and easy to clean.

- Spills and contaminants cannot penetrate and are easily wiped away.

4. Slip resistance:

- The textured finish from flakes, metallics, and quartz aggregates provides better traction and slip resistance compared to smooth coatings.

5. Chemical and moisture resistance:

- These coatings act as a protective barrier against chemicals, oils, moisture, and other damaging substances.

6. UV stability:

- Many flake, metallic, and quartz coatings are UV-resistant, preventing fading and discolouration from sunlight exposure.

Overall these floor coatings can elevate concrete surfaces both aesthetically and functionally, providing decorative appeal along with superior durability, easy maintenance, and chemical/moisture resistance, making them suitable for various residential and commercial applications.

Epoxy Flake Floor Process

Firstly, it's recommended that you clean the surface to remove any dirt, grease, or contaminants, and then mechanically profiling the concrete through methods like shot blasting or diamond grinding. This creates a rough, porous surface that allows the coating to mechanically bond and adhere properly.

Once the surface is prepared, whether new or existing, the application process for flake, metallic, and quartz coatings is generally similar. It often involves:

-

Applying a primer or epoxy base coat to enhance adhesion and seal the concrete surface.

-

Broadcasting or sprinkling the decorative flakes, metallic particles, or quartz aggregates onto the wet base coat.

-

Applying a clear topcoat or sealer over the decorative layer to provide protection and a glossy finish.

The ability to use these coatings on both new and existing concrete surfaces makes them a versatile option for various residential and commercial projects, including garage floors, patios, showrooms, and more, allowing for a customised and visually appealing finish while providing durability and protection.